Automated Jar Inspection System

A leap towards automated quality assurance in food production lines

The Challenge: Overcoming Manual Inspection Limitations in Jar Filling System

In the ever-evolving landscape of food manufacturing, ensuring the highest quality of products is paramount. Our client, an international food manufacturer, reached out to us at Adbro Controls to address a pressing issue they were facing. Their current jar filler system relied heavily on manual checks, which not only proved time-consuming and costly but also opened the possibility for human error.

Given the system’s limitations, the client sought our expertise to develop a technologically advanced solution, specifically an automated jar inspection system. This system would be designed to perform meticulous checks on various product elements, eliminating human error, increasing efficiency, and reducing operational costs. The complexity of the challenge lay in dealing with jars of different shapes and sizes, filled with diverse food products such as mayonnaise, mustard, and salad dressing.

The Solution: Streamlining Quality Control with an Automated Jar Inspection System

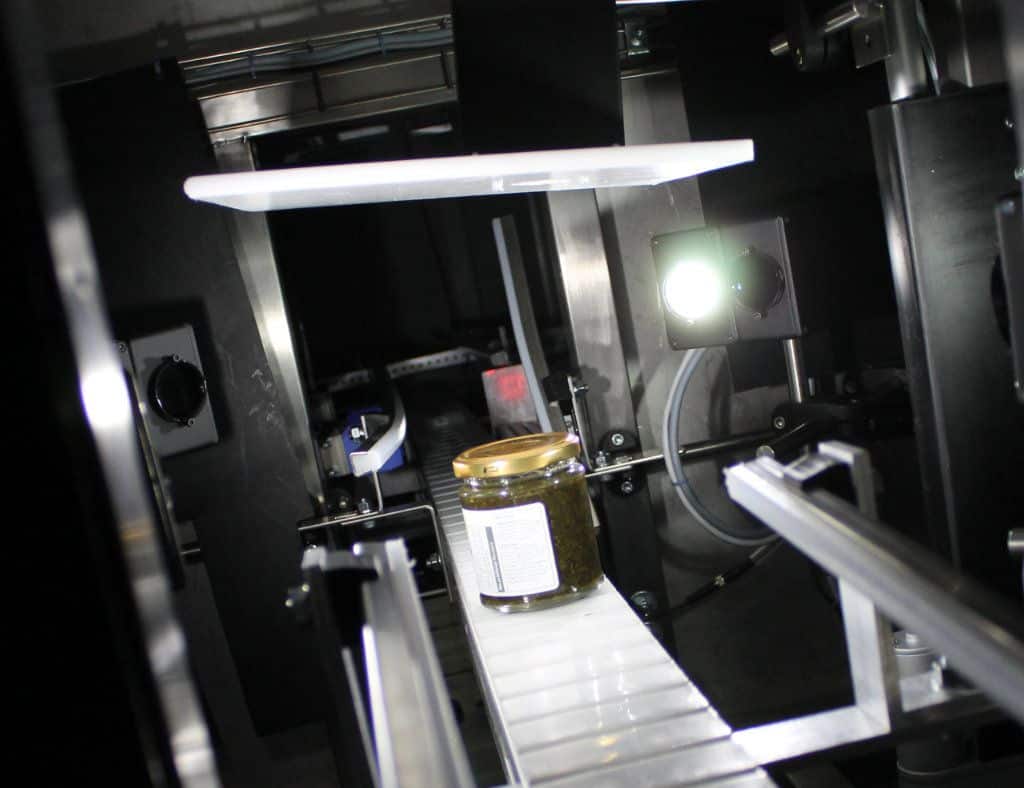

To address this challenge, our engineers at Adbro Controls harnessed their extensive vision knowledge to create an all-encompassing solution. We developed a state-of-the-art automated jar inspection system for this specific application. Our system integrated multiple cameras and sensors that could effectively track and monitor the food jars moving on a conveyor belt at a speed of 0.5m/s.

Here’s an overview of how we implemented this breakthrough solution:

- Multi-Camera Set-Up: We mounted five Blackfly colour cameras from Point Grey strategically within the system to capture a 360° image of each jar. Four cameras were positioned in the x/y plane, 300mm away from the jar to capture images from all sides. The fifth camera was designed to move vertically to accommodate different jar heights, capturing an image of the top of the jar.

- Lighting and Reflection Control: To prevent the imager in the camera directly opposite from being saturated by light from white light LEDs, we equipped each camera and light with a polarizing filter.

- Real-Time Position Tracking: We integrated an opto-reflective sensor from IFM Electronic and a DFS60 encoder from SICK. This combination allowed us to accurately track the position of each jar on the conveyor belt.

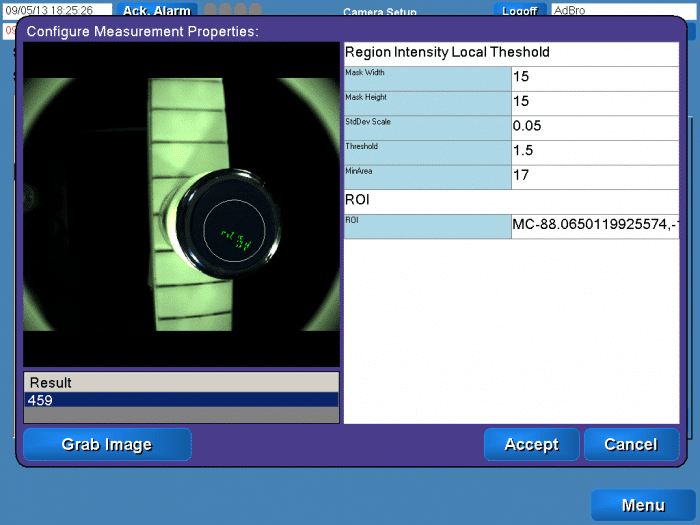

- Versatile Software Solution: Our team developed bespoke software components using the C# object-oriented programming language. This software calculated the position of the jars, controlled the image acquisition, and detected faulty jars. If a fault was identified, a pneumatic rejection system was activated to remove the jar from the line.

- Integrated Image Processing: The image processing component incorporated different C# classes created for each inspection procedure. These classes utilized image processing routines from the HALCON vison library from MVTec Software.

- User-Friendly Interface: The HMI interface component, written in C#, enabled users to modify the properties of image processing routines associated with specific operations through a graphical user interface.

- Flexible System Training: The system was trained to identify and locate a specific type of jar in an image. We created a shape-based model of the curved region from the top of the jar’s cap to its body, which was unique to each product type.

This automated jar inspection system was an innovative solution that not only met the client’s needs but also had the potential to redefine the standards of quality control in the food manufacturing industry.

The Results: Transforming Quality Assurance with Automation

After we deployed this breakthrough solution, it proved to be a game-changer in the client’s food manufacturing process. The company observed significant improvements in their quality control checks. We installed two of these automated jar inspection systems on site, providing this food manufacturing company with a more efficient, reliable, and cost-effective solution.

Let’s look at the tangible outcomes that were achieved:

- Increased Efficiency: The system was capable of inspecting jar food products at an impressive rate of 150 jars per minute, significantly improving the production line’s overall efficiency.

- Versatility: The design of the inspection system allowed it to be reconfigured for different inspections as needed, proving to be a versatile solution that could adapt to the company’s evolving needs.

- Statistical Data and Reporting: The system software maintained a statistical database, providing crucial insights into the type of rejects (missing labels, seals, or date codes) occurring. It also generated data on how many inspection parameters, such as the colour of the labels, were within specification during a production run. Additionally, the system could produce Excel spreadsheet files for production personnel to visualize the statistical data, assisting in informed decision-making.

- Remote Analysis: The system could export images of jars from a production run, enabling remote engineers to analyse the system’s effectiveness and perform any necessary software modifications.

Our automated jar inspection system proved to be a tremendous asset for our client. Not only did it streamline their quality control processes, but it also enhanced their operational efficiency and enabled them to continue delivering top-quality products. By integrating cutting-edge technology, innovative software solutions, and a user-friendly interface, we were able to help our client stride confidently into a new era of automated quality assurance.

Adbro Controls continues to pioneer in developing intelligent automation solutions, revolutionizing quality control processes in the manufacturing sector. We strive to meet the unique needs of each client and deliver customized, high-quality solutions that enhance efficiency, reduce costs, and ensure product reliability. We believe that our success is deeply intertwined with the success of our clients, and we are dedicated to fostering their growth through advanced, practical automation solutions.