Machine Builds and Retrofits

Revitalize your manufacturing operations

Improve, Upgrade, Automate

At Adbro Controls, we understand that your industrial manufacturing operations require precision, reliability, and efficiency to stay competitive. Your machinery and systems are the lifeblood of your production line, and any downtime or inefficiency can significantly impact your bottom line. That’s where our expert machine builds and retrofits services come into play. We work closely with you to breathe new life into your existing machines or design and build bespoke machinery tailored to your exact needs.

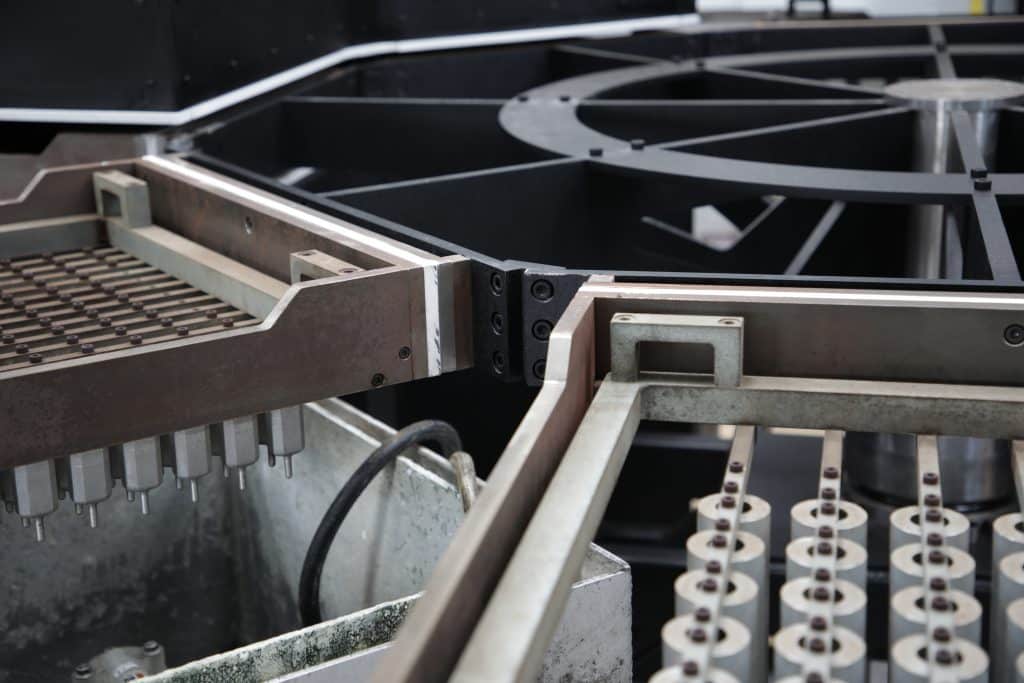

Machine Builds, Turning Your Vision Into Reality

Got an idea? We will transform it into a reality. From conceptualization to the final build, our dedicated team ensures your vision is at the core of the machine build process.

Our machine builds are much more than just manufacturing machines. They’re an opportunity to reimagine your production line. We begin with your unique specifications and requirements, which we develop into a detailed design using advanced engineering and automation techniques. Every aspect of your project is managed meticulously, from concept development through to the final machine build. We’re committed to creating a machine that not only meets your manufacturing needs but surpasses your expectations in terms of performance and efficiency.

Our engineering team is well-versed in diverse areas such as robotics, motion control, vision systems, and machine safety. Whether you’re looking for automation systems for pharmaceutical manufacturing, custom robotics for the aerospace industry, or precision machinery for the automotive sector, we have the knowledge to create innovative solutions that help streamline your production, improve product quality, and boost your operational efficiency.

Machine Retrofits, Revitalizing Your Existing Machinery

In an era marked by rapid technological advancements, your machinery may be becoming a bottleneck in your production process. Sometimes, a touch-up is all it takes to transform your existing machinery into a powerhouse of productivity. This is where our retrofit services come into play.

Through enhancing the capabilities of your current machinery, our retrofits can avoid the need to invest in costly new equipment. Whether it’s replacing outdated control equipment with modern, more efficient systems, or mechanical upgrades for increased durability and reliability. Our goal is to enhance the lifespan, performance, and reliability of your machinery while minimizing downtime and disruption to your operations.

We routinely perform retrofits on a wide array of machines, from industrial packaging machinery in the food and beverage sector to advanced manufacturing systems in the automotive industry. Whether it’s a simple component upgrade or a complete system overhaul, we provide the most appropriate and cost-effective solution to your machinery improvement needs.

The Process, Your Journey Towards Enhanced Efficiency

The first step in our machine builds and retrofit service is an in-depth consultation and evaluation of your current operations and requirements. We then develop a detailed project plan, outlining the key objectives, milestones, and deliverables. Our multidisciplinary team of engineers and designers will then work collaboratively to bring the project to fruition, ensuring regular communication and progress reports along the way.

Following the design and build or retrofit of your machine, we conduct thorough testing and quality assurance checks to ensure optimal performance. We also provide comprehensive training and support to your staff to ensure seamless integration into your existing operations. Our after-sales support is second to none, and we’re always on hand to provide advice, maintenance, and any necessary tweaks or updates.

Benefits of Machine Builds and Retrofits

Our machine builds and retrofits service provides a host of benefits that elevate your operations:

- Increased Efficiency: Boost your productivity with machines that run faster, smoother, and with less downtime.

- Improved Quality: Enhance the precision and consistency of your production, ensuring superior product quality.

- Cost-Effective: Prolong the life of existing machinery, reducing the need for costly replacements.

- Future-Ready: Stay ahead of the curve by integrating technology that accommodates future updates and innovations.

In a world where precision, speed, and efficiency are paramount, Adbro Controls is committed to providing you with the engineering solutions you need to stay at the forefront of your industry. Our machine builds and retrofits services offer a cost-effective, high-performance solution to the challenges you face in your manufacturing operations. No matter the complexity or size of your project, we strive to deliver innovative, robust, and efficient machinery tailored to your unique needs.

Your Success, Our Mission

At Adbro Controls, we believe in a partnership approach. Don’t let outdated or inefficient machinery hold back your manufacturing operations. Let us help you enhance productivity, reduce operational costs, and create a competitive edge in your industry. Reach out to our team today to discuss your needs and learn how we can help your manufacturing operations reach new heights of efficiency and excellence.

Your vision, our innovation and expert execution. Together we can build the future of your manufacturing process.

Having worked with the Adbro Controls team over many years, I have confidence in their ability to understand any problematic situations or issues and come up with a suitable solution. Their attention to detail is second to none, specialising in URS (User Requirement Specification) taking time to listen carefully to what is required. I am always happy with their execution of projects and this is why I have used them on mulitple occasions when working for different employers.